DESCRIPTION:

Electrodialysis is a widely used technique for separating ions and molecules in a solution. It involves the use of an electric field to drive ions through a selectively permeable membrane, which allows certain ions to pass while blocking others. One critical component of electrodialysis systems is the spacer, which is designed to create a uniform flow of the solution through the system.

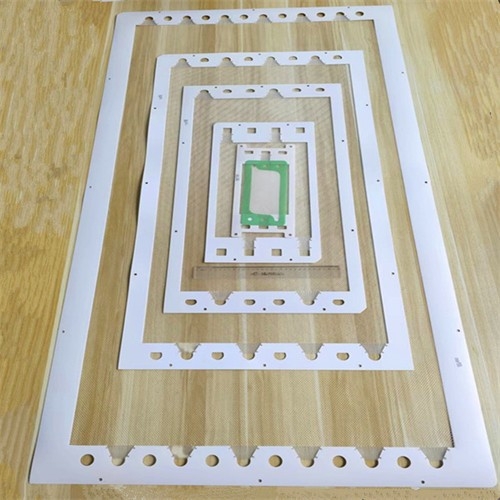

The electrodialysis spacer is a critical component of the system because it determines the efficiency and effectiveness of the process. The spacer serves to separate the membranes in the stack and provide a channel for the solution to flow through. The goal is to maintain a consistent distance between the membranes to ensure that there is a uniform electric field across the entire system.

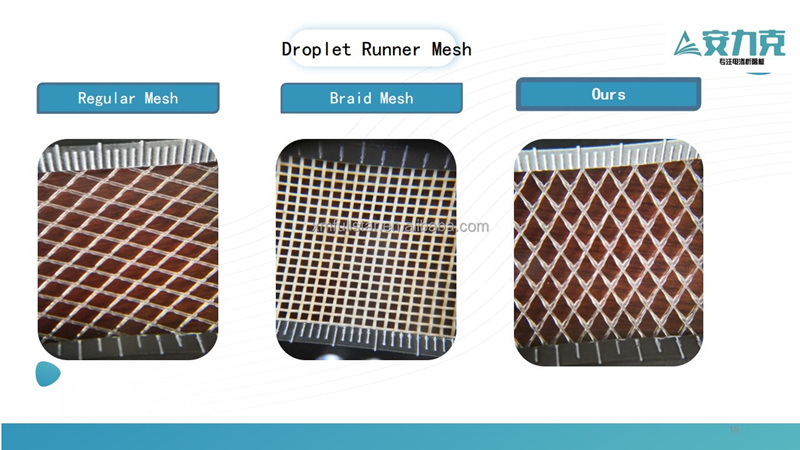

There are different types of spacers used in electrodialysis systems, including monofilament, woven, and extruded spacers. Monofilament spacers consist of a single filament that is wound around the membranes to create a gap. Woven spacers are made from woven mesh, and extruded spacers are made from a plastic material that is extruded into a desired shape.

Electrodialysis spacers are used in a variety of applications, including desalination, food and beverage processing, and pharmaceutical manufacturing. In desalination, electrodialysis systems are used to remove salt from seawater to make it safe for drinking and irrigation. In the food and beverage industry, electrodialysis is used to remove impurities and adjust the pH of the product. In pharmaceutical manufacturing, electrodialysis is used to purify and concentrate solutions.

Introducing Our Revolutionary Electrodialysis Spacer: Taking Water Treatment to New Heights!

At FULLSTAR, we are proud to be at the forefront of innovation in the field of water treatment. We are excited to announce the launch of our groundbreaking product, the Electrodialysis Spacer, which is set to revolutionize the way we purify water. With its cutting-edge design and unmatched performance, our spacer is poised to redefine the boundaries of electrodialysis technology.

Tackling Water Treatment Challenges Head-On

Water scarcity and the need for sustainable water management have become critical issues globally. As industries and populations grow, traditional water treatment methods struggle to keep up with the demand for clean water. Enter our Electrodialysis Spacer, a game-changing solution that addresses these challenges with unparalleled efficiency and effectiveness.

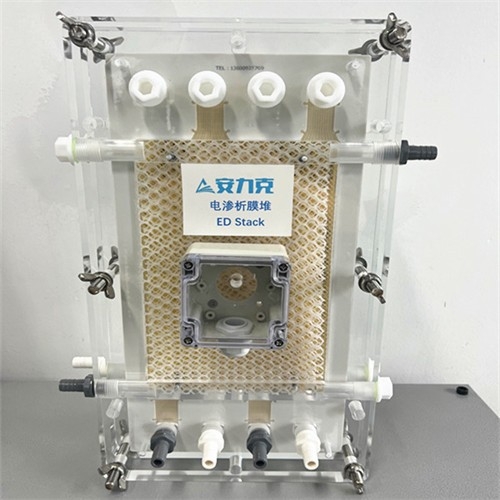

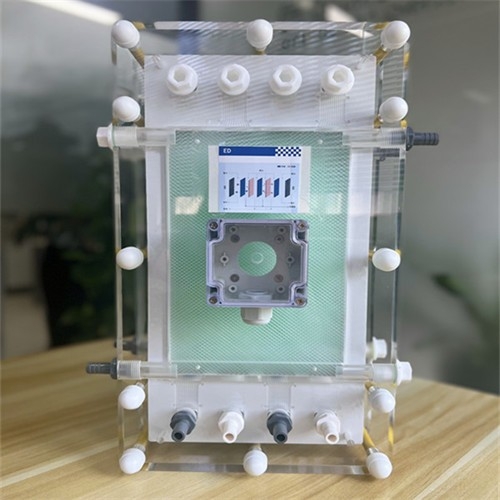

PRODUCTION PROCESS:

| Item | Value |

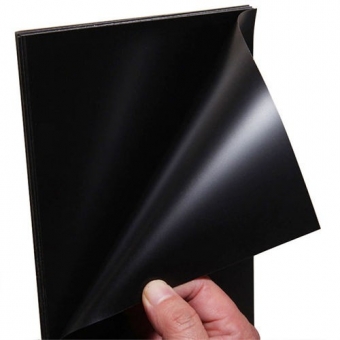

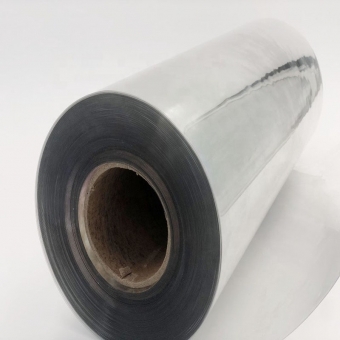

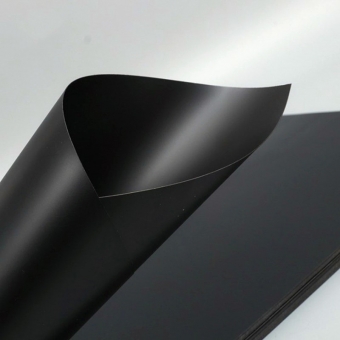

| Material | Special High quality PP sheet |

| Applicable Industries | Manufacturing Plant, Farms, Printing Shops, Construction works , Energy & Mining, wastewater treatment |

| Machinery Test Report | Provided |

| Size | 300*140 / 200*400 / 250*500 / 410*810 / 560*1110 / 800*1600 MM |

| Productivity | 1000pcs/day |

| Place of Origin | China |

| Video outgoing-inspection | Provided |

| Samples | Available |

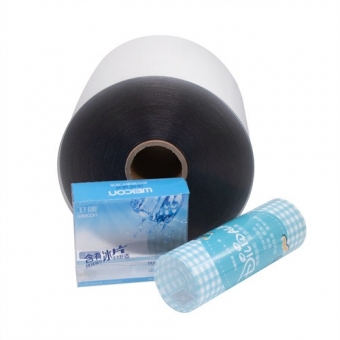

| Packing | Wooden pack with film |

Unleashing the Power of Electrodialysis

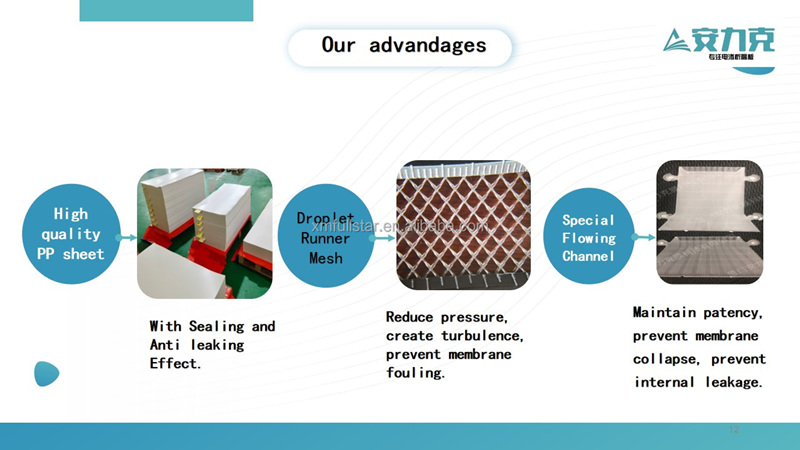

Electrodialysis has long been recognized as an efficient and environmentally friendly method for desalination, purification, and concentration of various aqueous solutions. However, the performance of electrodialysis systems heavily relies on the spacer material, which plays a crucial role in optimizing the process. Our Electrodialysis Spacer boasts several remarkable features that set it apart from conventional spacers:

(1)Enhanced Ion Transport: Our spacer is meticulously engineered to facilitate rapid and precise ion transport, resulting in improved separation efficiency and reduced energy consumption.

(2)Superior Durability: Designed with the highest quality materials, our spacer demonstrates exceptional resistance to fouling,scaling, and chemical degradation, ensuring long-lasting performance and reduced maintenance costs.

(3)Versatile Applications: Our spacer is versatile and adaptable, making it ideal for a wide range of electrodialysis applications,including water desalination, brackish water treatment, wastewater recovery, and more.

Paving the Way for a Sustainable Future

At FULLSTAR, we are committed to sustainability and environmental stewardship. Our Electrodialysis Spacer aligns perfectly with this vision by offering numerous eco-friendly benefits:

(1)Energy Efficiency: By optimizing ion transport and minimizing energy losses, our spacer contributes to significant energy savings, reducing the carbon footprint of water treatment processes.

(2)Water Conservation: Our spacer's high separation efficiency enables the recovery and reuse of valuable water resources, fostering responsible water management practices.

(3)Chemical-Free Operation: Thanks to its exceptional resistance to fouling, our spacer eliminates the need for harsh chemicals,promoting a cleaner and greener water treatment process.

Join the Water Treatment Revolution Today!

Are you ready to embark on a new era of water treatment excellence? Partner with FULLSTAR and harness the power of our groundbreaking Electrodialysis Spacer. Our team of experts is dedicated to providing customized solutions tailored to your specific needs, ensuring optimal performance and maximum cost-effectiveness.

Contact us today to learn more about our Electrodialysis Spacer and how it can transform your water treatment processes. Together, let's create a sustainable future where clean water is accessible to all.

Q1: How many countries you already exported ?

A1: Exported to more than 50 countries mainly from the United States, Russia, UK, Australia, Egypt, Canada, Turkey,

India, Republic of South Africa, Indonesia, Philippines etc.

Q2: How can I get some samples?

A2: Small samples in store and can provide the samples for free, but you need to pay for the postage fee. Directory is

available, most patterns we have ready samples in stock. Customized samples will take about 5-7days.

Q3: How about the delivery time?

A3: Sample order’s delivery time is 3- 5days. 20 feet Container ordersare around 10-15 days after receiving confirmed

deposit.

Q4: How does your company do regarding quality control?

A4: The SGS Report, FDA Certificates, QS Certificates, production process with the ISO 9001 System.

Q5: How to get the product quotation?

A5: Please tell us your required material & material purpose & width & thickness & quantity.

Q6: How long is your lead time?

A6: Most of the goods in stock, if there is no stock, the delivery is usually 5-10 days.

Q7: What are your payment terms?

A7: 30% in advance by T / T, balance before shipment.

PACKING DETAILS:

fullstar@xmfullstar.com

fullstar@xmfullstar.com

en

en ru

ru es

es

IPv6 network supported

IPv6 network supported